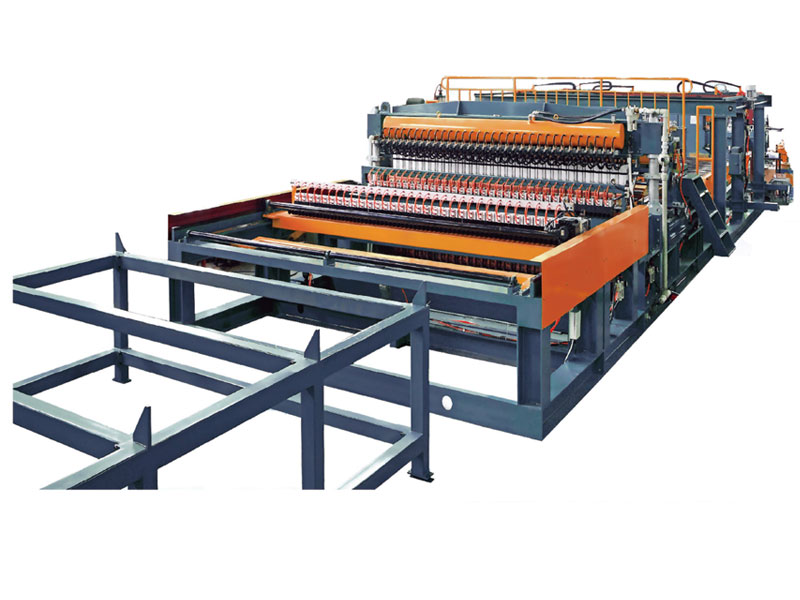

SKZM3300 series wire mesh welding machine is complete equipment for welding wire mesh, which is manufactured by SKZ based on learning foreign advanced experiences and advanced technologies in addition to actual production demands in the international market. This series equipment can perform high quality cross-welding for hot-rolled ribbed rebar, cold-rolled ribbed rebar, and round rebar. It has many favorable features, such as high output, high precision, easy modification, low operation failure rate, strong capability in energy saving, low consumption, and high quality.

Highlights:

- The main operating parts can be driven by pneumatic components or servo motor;

- The equipment adopts CNC controlling; it is possible to adjust the width of wire mesh and the mesh spacing, the size precision is high, and the mesh sheet with different mesh spacing can be welded automatically.

- This machine is equipped with a touch-style control screen. With it, the operating status of equipment can be viewed, and equipment operating parameters and welding parameters can be adjusted easily.

- International famous trademarks are selected for key driving parts, actuators, and electric/pneumatic components; the life cycle is long, and the precision is high.

- The system is equipped with alarm system, which can monitor and control the pressure of cooling water, air pressure, and various positions, so the normal operation of equipment can be guaranteed.

- Less sparks and low noise during the welding process;

- Easy operation and simple maintenance;

- The entirety type foundation for whole machine is easy to install.

- Reasonable equipment layout and beautiful appearance;

| Model | KZH3300X |

| Material | pre-cut, low carbon coLd-rolled wire or cold-drawn uncoated wire |

| Max. mesh width (cross wire Length)(mm) | 3300 |

| Max. oulmost line wire dimension (mm) | 3100 |

| Max. mesh length (line wire length)(mm) | 6000 |

| Line wire spacing (mm) | 100 – 300, multiples of 50 |

| Cross wire spacing (mm) | ≥50, programmable adjustable |

| Line wire diameter (mm) | φ5-φ12 |

| Cross wire diameter (mm) | φ5 -φ12 |

| Max. welding capacity (mm) | φ12 + φ12 |

| Max, welding speed (strokes/min) | 50-70 |

| Air pressure (Mpa) | 0,6-0-8 |

| Cooling water pressure (Mpa) | ≥0.3 |

| Numbers of welding transformer (Mpa) | 16 |

| Numbers of electrode | 32 |

| Labeled electric powor (KVA) | 16 x 100 |

CN

CN