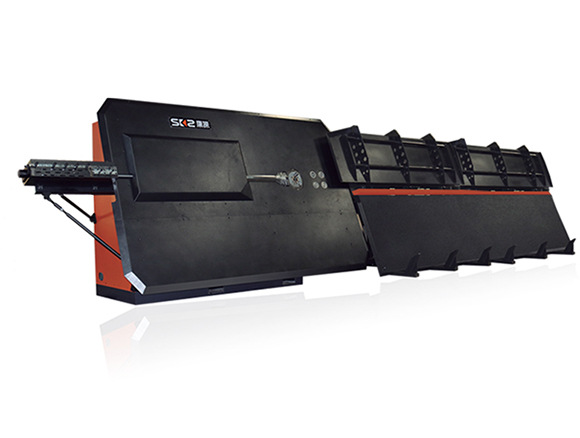

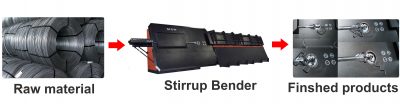

This machine is a fully automatic intelligent steel bar bending machine, which integrates straightening, positive bending and reverse bending forming and cutting four functions in one, steel bar hoop and one-time forming; it has less auxiliary labor, fast processing speed, high precision and high processing efficiency. The long service life and other characteristics are the high-tech products independently developed by our company with independent intellectual property rights. The equipment is the first in China and fills the domestic technical gap. This machine is required to use multi-point support rack feeding. The multi-point support rack is another patented product developed by our company for the domestic construction market. The feed rack is smooth and easy to install and easy to use. The service life of the straightening mechanism is extended and the straightening effect of the steel bar is improved. In short, our products are close to the market, strive to diversify, meet user needs, simple and effective, to reduce costs and bring benefits to users.

Model | KZ12CX |

Raw materrial | Coil |

Single wire Diamter(mm) | φ5-13 |

Double wire Diamter(mm) | φ5-10 |

Max Bending Angle(°) | 180 |

Max Pulling Speed (m/min) | 100 |

Max Bending Speed(°/s) | 1000 |

Bending Direction | Bi-direction |

Length tolerance (mm) | ±2 |

Bending Tolerrance (°) | ±1 |

Single wire Max Production capacity(hour) | 900(standard size) |

Double wire Max Production capacity(hour) | 1800(standard size) |

Equipment Sizes (mm) L*W*H | 4000*1080*1975 |

Installed Power (kw) | 30 |

Finshed products(12m long) | |

Weight(kg) | 3500 |

Working (℃) | -5-40 |

Cylinder Pressure (Mpa) | ≥0.6 |

Product Features

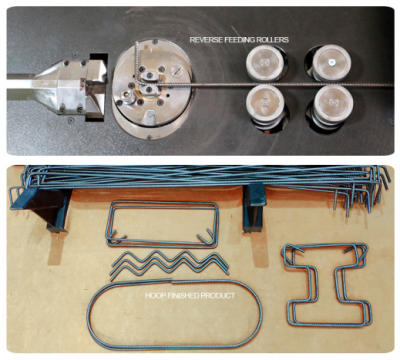

1. Machinable stirrups, ribs

2. Reverse feeding mechanism, compact structure and automatic alignment function enable stable transmission when the steel bars are reversely bent

3. Adjustable receiving rack, expand and extend according to processing needs, more humanized design

4. Intelligent graphical interface, real-time display of processing shape in the operation interface, the operation is more intuitive

5. Select high-performance PLC, anti-interference, powerful software functions, precise processing method to make the positioning of the control system more precise

CN

CN